Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Blog Article

All Concerning Industrial Scales: Key Attributes and Advantages for Your Office

Industrial ranges are essential in enhancing functional efficiency across numerous industries, supplying features such as high capability, precision accuracy, and durable construction. These instruments not just lessen human error yet also promote data assimilation and governing conformity, making them crucial for quality control and product administration. As companies significantly acknowledge the relevance of these devices, the ramifications for productivity and waste reduction end up being significantly substantial. Understanding the varied types and applications of commercial ranges can give important understandings right into maximizing your office procedures-- yet, the journey does not end there.

Sorts Of Industrial Scales

Industrial scales are vital devices utilized across various industries for precise weight dimension. They come in a number of types, each developed to satisfy specific applications and environments. One common type is the system range, which offers a large weighing surface perfect for cumbersome and hefty things. These ranges are usually used in storage facilities and shipping facilities.

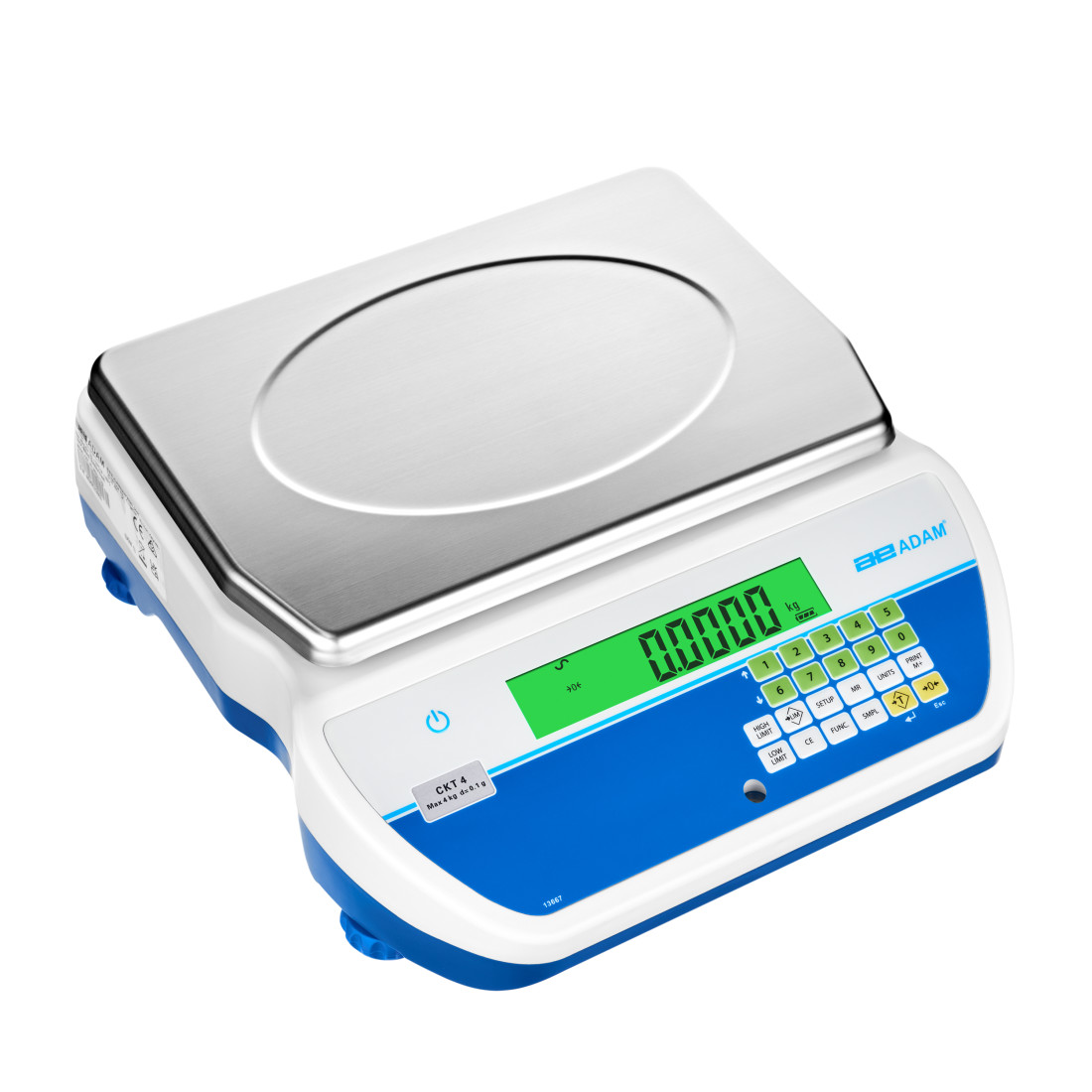

An additional common type is the bench range, which is appropriate and portable for smaller sized items. These ranges are regularly discovered in retail and food service environments, where quick and accurate dimensions are needed. Floor scales offer a similar purpose yet are designed for sturdy applications, permitting for the weighing of huge pallets and containers straight on the ground.

Moreover, electronic scales have obtained popularity as a result of their simplicity of use and precision. They commonly feature sophisticated electronics that enhance capability, such as connection alternatives for information monitoring. Furthermore, mobile ranges use flexibility for on-the-go evaluating, making them important in areas like agriculture and logistics.

Comprehending the various kinds of industrial scales is crucial for picking the best tools to fulfill particular functional demands, ensuring effectiveness and accuracy in weight measurement.

Secret Features of Industrial Scales

When selecting the suitable kind of commercial range, it is essential to think about the vital attributes that enhance their functionality and suitability for details applications. Among one of the most critical features is the scale's ability. Industrial ranges are available in various weight capacities, guaranteeing that they can accommodate the needs of different sectors, from light products to heavy loads.

An additional essential attribute is accuracy. High-precision lots cells are essential for making sure that measurements are reputable and constant, which is essential for inventory management and quality assurance. In addition, the readability of the display screen plays a considerable function; clear, electronic screens with adjustable brightness enable for easy watching in various lights problems.

Durability is an additional crucial characteristic, with several industrial scales created to endure harsh atmospheres, including direct exposure to moisture, chemicals, and hefty usage. Some designs also include waterproof or stainless-steel building. Connectivity options such as Bluetooth or USB allow smooth data transfer and assimilation with other systems.

Benefits for Workplace Effectiveness

Additionally, commercial scales allow faster handling times. With automated evaluating services, workers can rapidly obtain weight information without hand-operated estimations, maximizing time for various other vital tasks. This velocity in operations not just enhances operational performance yet likewise assists meet manufacturing due dates much more effectively.

Additionally, commercial ranges supply important information that can be examined for continual improvement. By keeping an eye on weight patterns, services can recognize inadequacies in their processes and implement rehabilitative actions, ultimately bring about boosted performance.

The assimilation of these ranges also sustains compliance with sector laws, as exact reporting of weights is often required. This reduces the danger of expensive penalties and enhances the firm's reputation for integrity. Industrial Scales. Generally, the unification over at this website of industrial ranges adds to an extra efficient, cost-efficient, and compliant office atmosphere

Applications in Numerous Industries

In the food market, industrial scales are used for section control, dish solution, and conformity with health and wellness guidelines, ensuring food security and uniformity. In the pharmaceutical sector, exact evaluating is important for drug formulation, where even minor discrepancies can lead to considerable regulative issues and safety concerns.

Construction and logistics industries likewise benefit from commercial ranges, as they help in handling basic materials and optimizing delivery processes. By providing precise weight data, these ranges promote better lots planning and compliance with transport regulations.

In addition, the agricultural sector uses industrial ranges for considering fruit and vegetables, feed, and animals, consequently boosting functional performance and making sure reasonable trade methods.

Maintenance and Calibration Tips

To make sure optimal efficiency and longevity of industrial scales, normal upkeep and calibration are necessary. A regular upkeep routine helps identify prospective problems before they rise, consequently lessening downtime and fixing expenses. Operators needs to routinely clean up the basics scale to stop debris accumulation, which can impact accuracy (Industrial Scales). Additionally, checking the tons cells, electrical wiring, and display screen for wear or damages is important.

Calibration is similarly essential; it makes sure that the scale provides exact analyses in conformity with industry requirements. It is a good idea to calibrate ranges routinely-- a minimum of as soon as a year or more regularly if the range is used heavily or moved regularly. Adhere to the manufacturer's guidelines for calibration treatments, which commonly consist of using certified calibration weights.

Moreover, maintaining appropriate environmental conditions, such as temperature and humidity control, can boost scale performance and precision. Lastly, training personnel on correct usage techniques will better secure against misuse that might result in errors or damage. By adhering to these upkeep and calibration tips, companies can guarantee their industrial ranges run successfully, inevitably supporting performance and conformity with regulatory criteria.

Conclusion

In summary, industrial scales function as essential tools for boosting ergonomics across varied sectors (Industrial Scales). Their high capability, precision accuracy, and long lasting building and construction add to ideal operations and quality assurance. The combination of innovative features, such as digital displays and data connectivity, additionally reduces human mistake and supports regulatory conformity. By comprehending the crucial attributes and benefits of commercial ranges, organizations can leverage these devices to more improve material use, minimize waste, and ultimately drive productivity.

Industrial ranges are essential in boosting operational efficiency throughout various sectors, using features such as high ability, precision accuracy, and robust building and construction.When selecting the ideal type of industrial range, it is important to think about the vital features that improve their functionality and suitability for specific applications. By providing precise weight dimensions, industrial scales remove the capacity for human error, guaranteeing that products are weighed consistently and precisely. It is advisable to calibrate ranges on a regular basis-- at least as soon as a year or more frequently if the scale is utilized heavily or relocated often. By recognizing the crucial functions and advantages of industrial scales, companies can leverage these devices to improve product usage, minimize waste, and ultimately drive performance.

Report this page